BENEFITS OF ALUMINIUM

Aluminium is not a substitute material!

As in any design, metals or other materials are chosen because of their suitability to perform under specified design conditions and according to overall least-cost parameters. Lifetime performance is relevant as is the return on investment. So, for example, when mass matters, such as in road vehicles on trailers, aluminium is usually the material of choice in that it affords greater payload as well as cost savings through reduced fuel consumption and less maintenance. It is also effectively rust-free under standard operating conditions.

The choice of materials by the designer involves seeking out options that are both effective and efficient and aluminium can hold its ground in many applications. The range of alloys allows the selection of an alloy most suitable to ensure the intended purpose is achieved and that financial returns over the product’s life cycle are achieved. Often, of course, aluminium is used most effectively in combination with other materials. It is the second most commonly used metal after steel.

Aluminium Properties and Assets – of importance to the designer.

Aluminium has been termed “The Magic Metal” or “The Wonder Metal”. The reasons for these accolades lie in the very diverse range of physical, chemical, and mechanical properties enjoyed by the metal and its alloys in both cast or wrought forms.

It is a versatile, highly usable and attractive construction material.

A key property is low density. Aluminium, with a density of 2,71 gm/cm3, is only one-third the weight of steel and less than one-third the mass of copper or brass.

A property that has resulted in extensive use of aluminium in fabricated ap- plications, replacing steel and other materials.

Whilst aluminium engineering alloys have similar strength to structural steels, aerospace aluminium alloys are even stronger than steel.

Aluminium is readily formed by a variety of processes (cast, rolled, extruded or forged and being malleable it is easily worked, formed and machined by the common manufacturing and shaping processes.

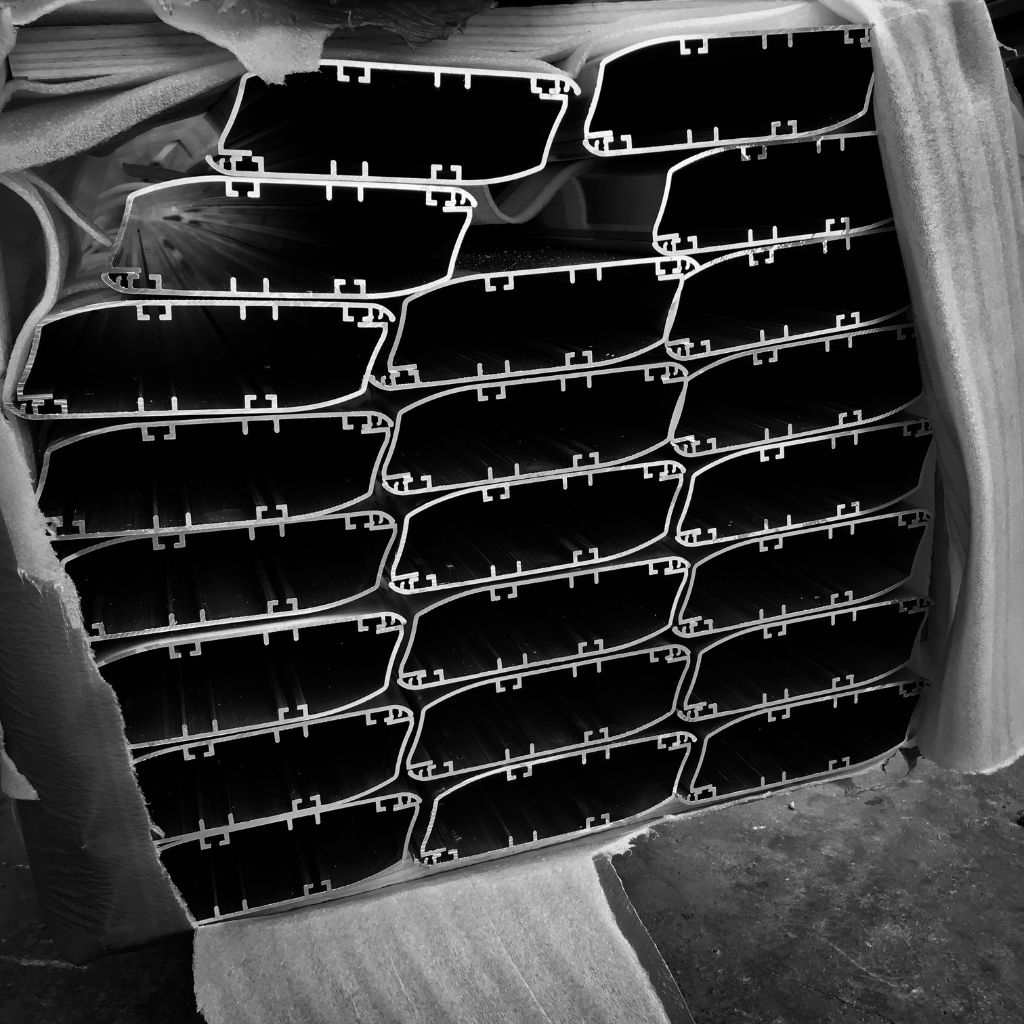

One of the real strengths of aluminium is in its extruded form. Extrusions are complex hollow and solid shapes that are able to incorporate a variety of features that increase the value of the product by reducing fabricating labour or increasing usability.

Is moderate, being about a third of that of mild steel, requiring stiffer aluminium sections. Has a relatively high coefficient of linear expansion.

Sheets, extrusions, sections and castings are easily joined by welding, braking, soldering mechanical fastening ana adhesive bonding.

Aluminium, and most of its alloys, are highly resistant to most forms of corrosion. The metal’s natural coating of aluminium oxide provides a highly effective barrier to the ravages of air, temperature, moisture and chemical attack (between the pH range 4.5 to 8,S), making aluminium a useful construction material. It does not rust.

Aluminium is a superb conductor of electricity. This property, allied with other intrinsic qualities, has ensured the replacement of copper by aluminium in many electrical applications. Mass for mass, aluminium conducts almost twice the electric current of copper.

ALUMINIUM SHEET DIMENSIONS

| Sheet Sizes (mm) | Kg’s per Sheet |

| 2000 x 1000 x 0,5 | 2.71 |

| 2500 x 1250 x 0,5 | 4.23 |

| 2000 x 1000 x 0,7 | 3.79 |

| 2500 x 1250 x 0,7 | 5.93 |

| 2000 x 1000 x 0,9 | 4.88 |

| 2500 x 1250 x 0,9 | 7.62 |

| 2000 x 1000 x 1,2 | 6.5 |

| 2500 x 1250 x 1,2 | 10.16 |

| 3000 x 1500 x 1,2 | 14.63 |

| 2000 x 1000 x 1,5 | 8.13 |

| 2500 x 1250 x 1,5 | 12.7 |

| 3000 x 1500 x 1,5 | 18.29 |

| 2000 x 1000 x 1,6 | 8.67 |

| 2500 x 1250 x 1,6 | 13.55 |

| 3000 x 1500 x 1,6 | 19.51 |

| 2000 x 1000 x 2,0 | 10.84 |

| 2500 x 1250 x 2,0 | 16.94 |

| 3000 x 1500 x 2,0 | 24.39 |

| 2500 x 1250 x 2,5 | 21.17 |

ALUMINIUM PLATE DIMENSIONS

| Plate Sizes (mm) | Kg’s per Sheet |

| 2000 x 1000 x 3 | 16.2 |

| 2500 x 1250 x 3 | 25.41 |

| 3000 x 1500 x 3 | 36.59 |

| 2500 x 1250 x 4,5 | 38.11 |

| 3000 x 1500 x 4,5 | 54.88 |

| 2000 x 1000 x 6 | 32.52 |

| 2500 x 1250 x 6 | 50.81 |

| 3000 x 1500 x 6 | 73.71 |

| 2500 x 1250 x 8 | 67.75 |

| 2500 x 1250 x 10 | 84.69 |

| 2500 x 1250 x 12 | 101.63 |

| 2500 x 1250 x 16 | 135.5 |

| 2500 x 1250 x 20 | 169.35 |

| 2500 x 1250 x 25 | 211.72 |

| 2500 x 1250 x 30 | 254.06 |

| 2500 x 1250 x 40 | 338.75 |

| 2500 x 1250 x 50 | 423.44 |

| 2500 x 1250 x 60 | 508.13 |

| 2500 x 1250 x 70 | 592.81 |

ALUMINIUM TREAD plate DIMENSIONS

| Plate Sizes (mm) | Kg’s per Plate |

| 5-BAR TREAD PLATE | |

| 2500 x 1250 x 1,5 (base) | 15,21 |

| 3000 x 1500 x 1,5 (base) | 21,9 |

| 2500 x 1250 x 2,0 (base) | 19,44 |

| 3000 x 1500 x 2,0 (base) | 27,99 |

| 2500 x 1250 x 3,0 (base) | 27,91 |

| 3000 x 1500 x 3,0 (base) | 40,19 |

| 2500 x 1250 x 4,5 (base) | 40,61 |

| 3000 x 1500 x 4,5 (base) | 58,48 |

| 2500 x 1250 x 6,0 (base) | 53,31 |

| 3000 x 1500 x 6,0 (base) | 76,77 |

| TREAD-BRIGHT PLATES | |

| 2438 x 1219 x 1,47 | 12,58 |

| 2438 x 1219 x 1,82 | 15,52 |

| 2438 x 1219 x 2,03 | 17,12 |

| 2438 x 1219 x 3,17 | 26,45 |